■ Main design difference

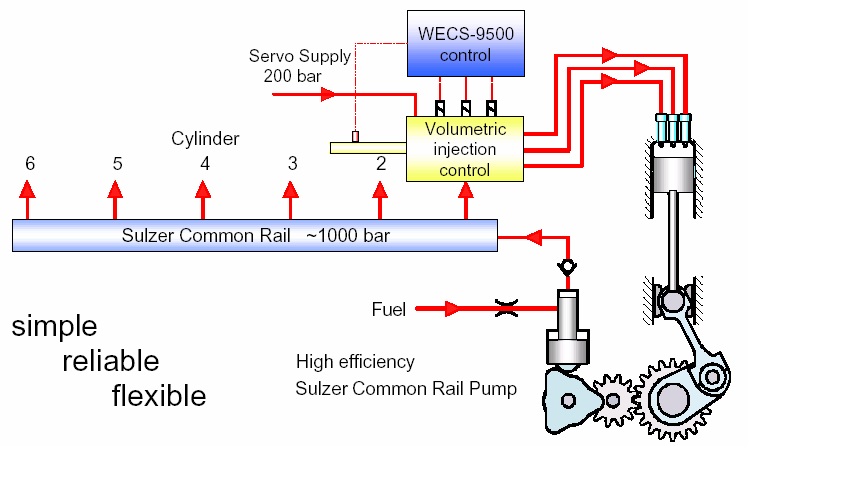

- Combined pressure generation and injection rate shape control

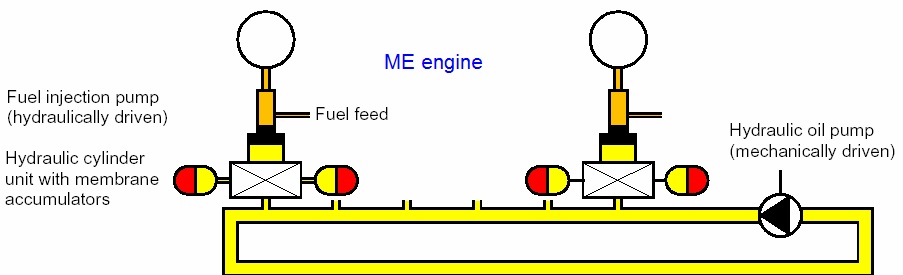

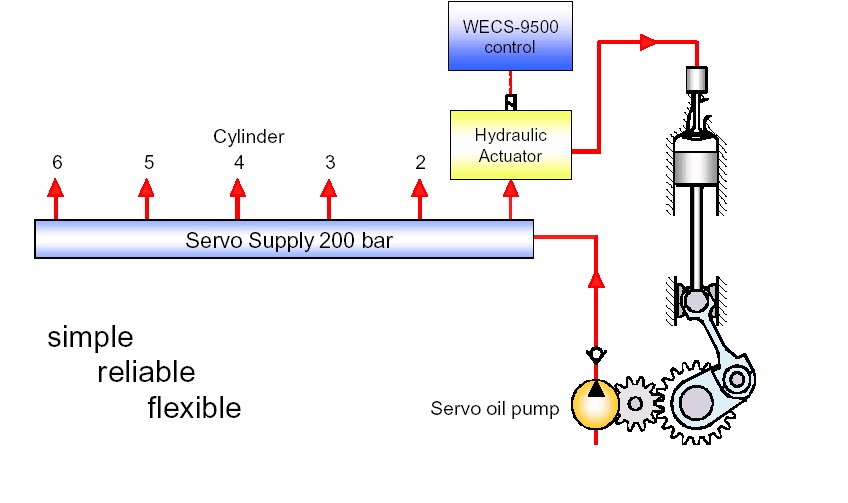

- One complete electro-mechanical hydraulic pump system per cylinder

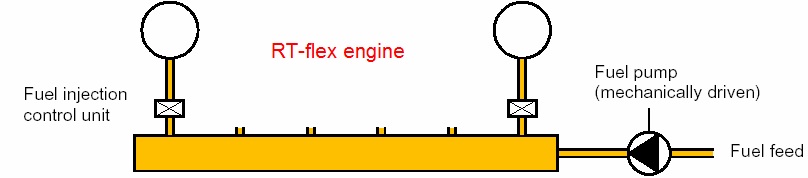

- Common rail vs. fuel is brought to high pressure at every cylinder station

- Single injection nozzle operation vs. no single injection nozzle

Under-slug receiver is WCH’s standard

for all new RT-flex96C/RTA96C engines

Advantages

- Increased margin against water carry over

- Simple welded construction

- Easy assembly

- Gallery arrangement for easy cooler dismantling

- Cooler arrangement for easy and efficient cleaning

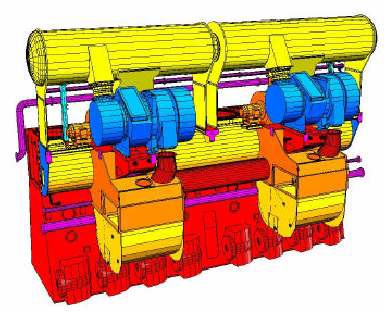

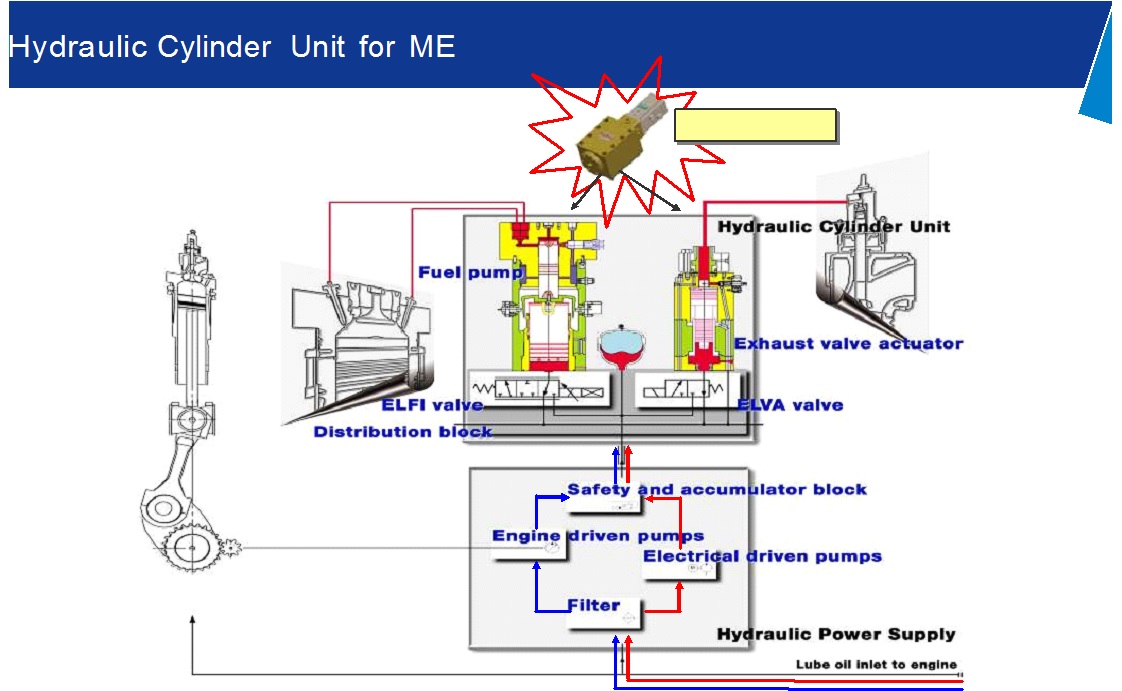

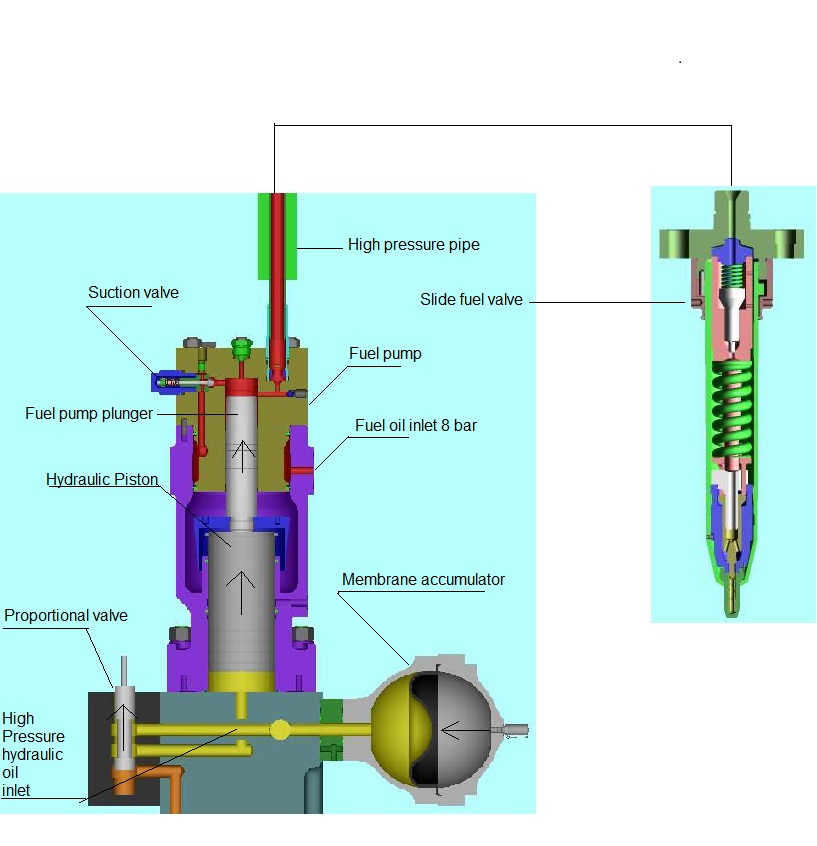

Hydraulic Cylinder Unit

The HCU, one per cylinder, consists of a support console on which a distributor block is mounted. The distributor block is fitted with a number of accumulators to ensure that the necessary hydraulic oil peak flow is available for the Electronic Fuel Injection(ELFI) and the Electronic exhaust Valve Activation(ELVA) systems.

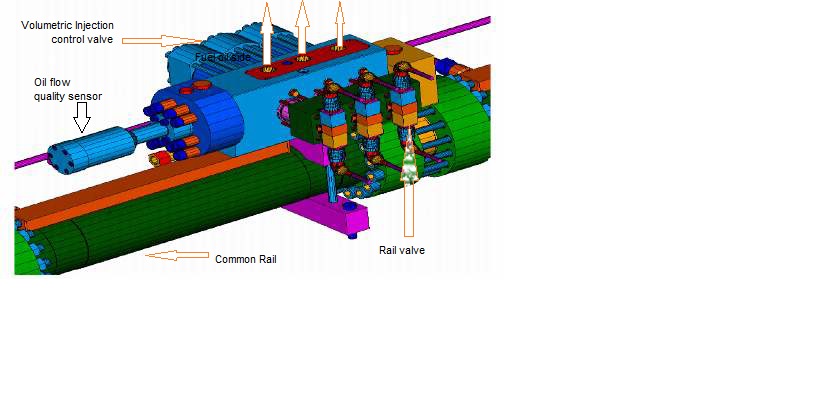

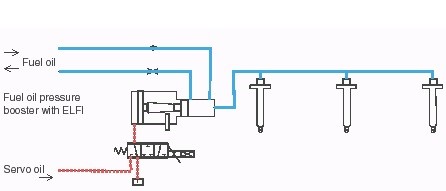

Common Rail system for RTFlex

Fuel system

Exhaust Valve Drive

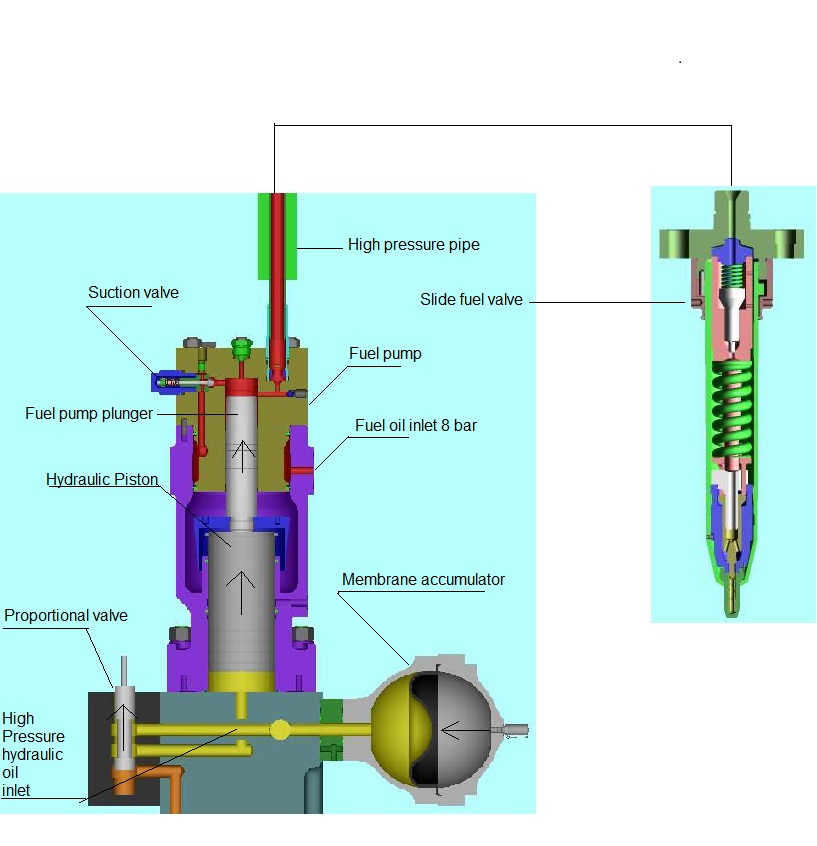

Fuel oil pressure booster with ELFI for ME (Elec. Fuel Injection)

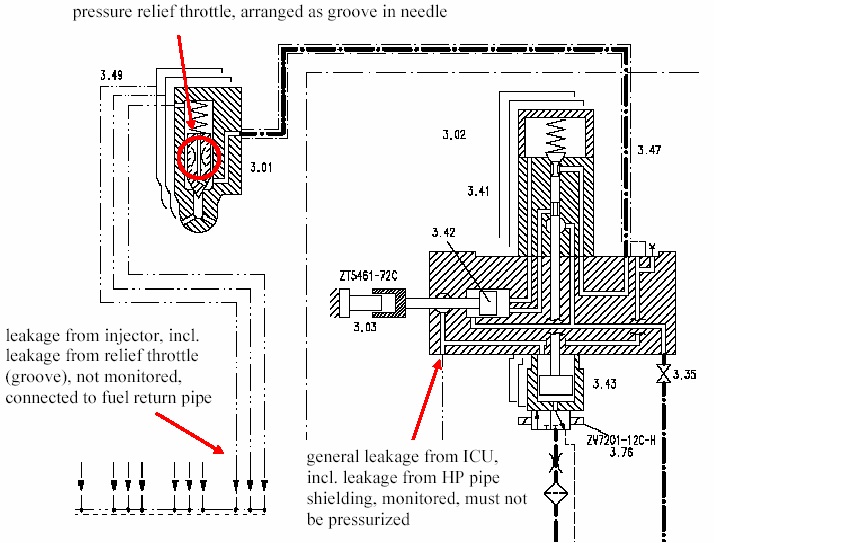

Fuel oil injection control valve with fuel valve for RT-flex (Elec. Fuel Injection)

- Shapes injection pattern

- Enables individual operation of every single nozzle

- Ensures precise fuel amount injected to each cylinder