A Number Of Incidents Came In Focous With High Top Ring Wear On Our Small Bore Engine Types 26 To 50. For This Reason, MAN B&W Has Introduced A New Piston Top Ring As Part Of The Standard Ring Pack Configuration For Their Two-stroke 26-50 Bore Engines.

On Small Bore Engines, The Smaller Depth Of The Controlled Leakage (CL) Grooves Reduces The Wear Potential Of The Piston Top Ring Compared To The Large Bore Engine Types. In Some Cases Premature Wear Out Of The Controlled Leakage (CL) Grooves On The Top Ring Running Surface Can Be Seen. As A Result, The Pressure Drop Over The Top Ring Increased Further And Caused Increased Wear On The Top Ring, As Well As A High Liner Wear Rate And An Increased Ring Groove Wear.

To Remove The Negative Influence From Worn Out (CL) Grooves, MAN B&W Has Introduced An Alternative Ring Type To Replace The CPR-CL Ring. The New Ting Type Is Called CPR-POP (Port-On-Plane).

The Main Configuration With The Double S-lock And Gas Relief Grooves Remains Unchanged. The CL Grooves On The Runing Side Have Been Omitted And Replaced With A Number Of Ports Milled Into The Lower Side Of The Piston Ring These Passages Have Been Configured With A 90 Degree Narrowing, Causing The Ring To Increase The Bypass Area As The Ring Wears, Instead Of Reducing It When The Minimum Depth Is Reached, As Is The Case With The CL Grooves.

The Main Configuration With The Double S-lock And Gas Relief Grooves Remains Unchanged. The CL Grooves On The Runing Side Have Been Omitted And Replaced With A Number Of Ports Milled Into The Lower Side Of The Piston Ring These Passages Have Been Configured With A 90 Degree Narrowing, Causing The Ring To Increase The Bypass Area As The Ring Wears, Instead Of Reducing It When The Minimum Depth Is Reached, As Is The Case With The CL Grooves.

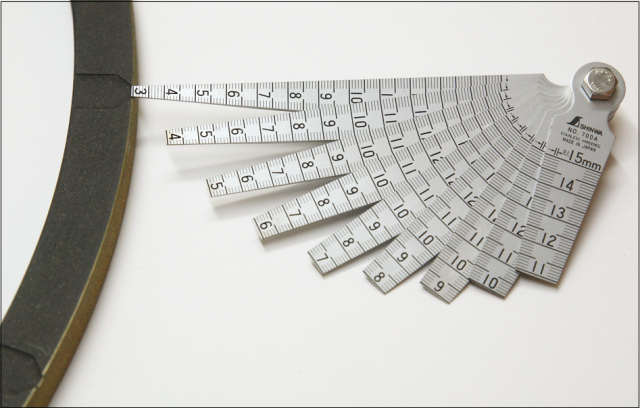

Thereby, The Pressure Drop Decreases Instead Of Increases. To Measure The Wear Of The Ring, The Width Of The Leakage Passage Can Be Measured Using A Feeler-gauge-type Measuring Tool. The Opening Is 3 Mm From The Beginning, And The Milled Passage Is Designed In Such A Way That For Every 1 Mm The Ring Is Worn Radially, The Gap Opens 2 Mm. Table 1 Lists The Maximum Allowable Width Of The Leakage Gap For Our Small Bore Engines.

Caution

There Is A Risk Of Liner Surface Hardening When Running With A Wornout Top Ring. Also There Is High Increase In Liner And Ring Wear Rates After Installing New Rings In A Liner Suffering From A Hardened Surface Can Occur Due To Running With Worn-out Piston Rings.If The Oil Film Between The Cylinder Liner And The Piston Rings Is Damaged, Adhesive Contact Will Occur, Followed By Temporary High Temperatures On The Surface And, Subsequently, Cooling, Results Hardening Of The Running Surfaces.

To Ensure Normal Wear Rates And Eliminate Surface Hardening,the Liner Surface Must Be Machined By Honing Or Grinding.